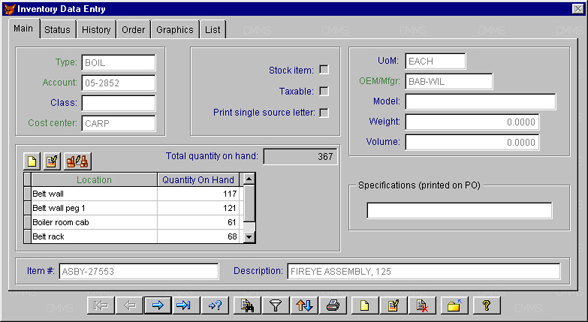

Scheduling: Plan and schedule tasks, assign resources, and track the progress of work orders, helping facilities managers optimize their resources and improve the overall workflow.This tracks repairs and other service-related operations. Service history: Record services performed on assets such as inspections, preventive maintenance schedule activity, etc.Inventory management: Track the items you have in stock, including the quantity, storage location, and usage, to ensure stock availability and timely reordering.Work order management: Create, manage, and organize work orders, helping you track the status of each work order, assign tasks to employees, and set due dates.

Preventive maintenance: Schedule routine checks, calibration, and regular parts replacement to prevent unexpected machinery breakdown and high maintenance costs or safety concerns.Asset tracking: Track all your assets, including their location, condition, and history, helping you monitor and manage the equipment within the premises.The software monitors the status of machinery on a regular basis, giving managers the alert notification of any abnormalities that might lead to unsafe conditions for employees. CMMS software can help prevent safety issues from arising by tracking equipment maintenance activity. Increased safety: When surrounded by machines, there is always the risk of an accident occurring.This reduces downtime and helps companies save money. CMMS software focuses more on taking a preventive step by enabling real-time monitoring of equipment, which helps in quickly identifying and resolving potential equipment problems. Many factors can cause downtime, but equipment failure is one of the most common reasons. It can interrupt production, disrupt service, and impact revenue. Reduced downtime: Downtime can be costly for any business.This reduces the risk of unexpected and costly repairs. The software also comes with a predictive maintenance feature that allows users to identify potential equipment failures before they occur and thereby take preventive measures. Cost control: A computerized maintenance management system monitors expenses on labor, parts, inventory, and other costs, enabling businesses to control unwanted expenses and save money.In addition, the CMMS system automates work schedules, helping the maintenance team plan, and implement the preventive maintenance task more efficiently, resulting in improved productivity. Improved efficiency: Tracking and managing maintenance processes digitally via CMMS software means fewer mistakes and less time wasted on manual tasks.The following are some of the most significant benefits of using the CMMS system:

0 kommentar(er)

0 kommentar(er)